Products

Flow Testers – Air Flow Testers

A wide range of flow testers for the measurement of flow rates from 10 mLPM to 500 LPM – the right device for every requirement.

AF-R220

- For testing leakage behaviour

- Touch-screen with intuitive operator interface and 32 programmes

Mass Flow Sensor

- Measurement under different test pressures

- No temperature or air pressure compensation required

- Measurement range from 500 mLPM to 500 LPM

Laminar-Flow-Sensor

- Measurement range from 10 mLPM to 100 LPM

- Durable and robust construction without moving parts

Measuring Device Combinations

Laminar-Flow-Sensorr & DF-2820

- Measurement ranges from 10 mLPM to 500 LPM

- Measurement with laminar flow pipes that provide high-precision readings of ± 1%.

- Automatic conversion into standard values

- LCD display for flow rate, temperature and ambient pressure

- Wide range of capabilities from component testing to laboratory applications

Mass-Flow-Sensor & DF-231BA

- Flow rate gauge with high-speed mass flow sensor

- No temperature or pressure adjustment required

Laminar-Flow-Sensor & DF-241BA

- Measurement range from 10 mLPM to 100 LPM

- Durable and robust construction without moving parts

Flow Rate Testers – Air Flow Testers

Air Flow Testers

- AF-2220

- AF-2400

Flow Rate Testers

- DF-230BA

- DF-240BA-N

Air-Mass Sensors

- DF-2820

Test Leaks

A comprising equipment programme provides you with complete solutions from one source.

- Production in Germany

- Unrivalled price

- Top-quality materials

- Traceability documentation

- Available with various adapters

Equipment for Process Support

Equipment Programme

- LM-1C

- QLC Series / LC Series

- MC Series

- G3-M/G3-ME

- BU Series

- NL-S2 Series

- PCL−04

- LMC-110

- DPI 800P

Valve Technology

The complete valve technology range is developed and produced in-house by Cosmo in Japan.

Bypass Unit

For fill time reduction for components with high filling volume and low test pressure.

External Bleeder Valve

External bleeder valve (G3-M) to reduce the risk of contamination of the measuring cell due to contaminated components.

Valve Combinations

Valves in combinations of two and three, depending on application.

Reference Chambers

Reference volume of the Cosmo range

- from 50 ml to 5000 ml

- Special arrangement of inner disks reduces impact of temperature drifts.

Cosmo Super Gel

Specially developed impermeable materials of the highest quality for leak testing.

Ring Testing Devices

Devices for acoustic resonance analysis for the detection of abnormal sounds.

Ring Testing Devices

Movelet

- MV-6000B

- MVA-600

Special Installations

Aside from our standard solutions with our modular systems we offer consultation, planning and implementation of complete installations. Our experienced service employees support you with the conception and integration of special installations for your individual testing requirements.

Leak Testing Devices – Air Leak Testers

Our leak testing devices are ideal for the integration in production lines – because only quality testing ensures high-quality products.

LS-R902

Touch-screen with intuitive operator interface

- Selection between 6 different display options

- Automatic null balance

- USB port for test data transfer

- Automatic compensation of temperature drift

- Selection between two measuring circuits: intelligent

- pneumatic circuit I (inner volume 11 ml) intelligent pneumatic circuit II (inner volume 13 ml)

LS-R910

For the testing of two different pressure ranges, e.g. vacuum and high-pressure, in one device

LS-R700

- Intuitive operator interface

- Selection between 3 different types of measuring displays

- USB interface for measurement data transfer

- Display accuracy ± 2.5% from reading values ± 1 Pa

- Air leak tester

LS-R740-(ZL,WZ)

(Volumetric air leak tester)

- For testing sealed, small components

Parallel Testing

- Parallel testing of up to 8 components

- Evaluation of all results via LCD touch-screen

- Easy connection of pneumatic units to control unit via field bus port

- Compact design

COSMO Differential Pressure Sensor

- Specially developed differential pressure sensor

- Measurement range depending on measuring device: ± 1,000 Pa or ± 10,000 Pa

- Linearity: ± 0.3% FS

- High sensibility up to 0.1 Pa

- Low tare volume of under 0.5 ml

- Volume alteration rate (depending on model): 0.01 ml/kPa or 0.005 ml/kPa

- Pressure load up to 5 MPa (standard) or up to 16 MPa (high-pressure edition)

Patented Air Leak Tester Features

Patented identification of the component volume

Patented volume measurement

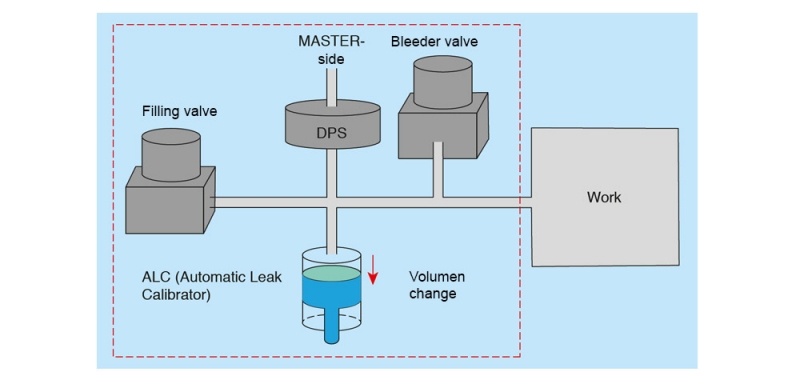

QLC: Extern

- To determine the equivalent inner volume of the tested component.

- To be screwed in at the front of the air leak tester.

ALC: integrated

- To determine the equivalent inner volume of the tested component.

- Installation in air leak tester as additional option

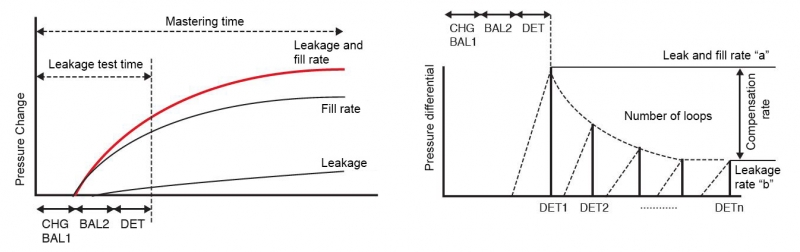

Patented Mastering

- Exact leak rate in shorter test time

- Determination of balance between the pressure differences in the measurement and the temperature effect in the iterative DET process.

Leak Testing Devices – Air Leak Testers

DP Leak Testers

Volume Air Leak Testers

- LZ-1550

- LZ-3000

Helium Leak Testing

- T-Guard

Digital Manometers

- DM-3501

- DM-3600

Digital Pressure Measuring Devices

- DP-340 / DP-340B / DP-340BA

Pressure Transducers

- PT-105A-A / PT-103B-A

- PT-161A / PT-162A

- PT-141C / PT-142B-A